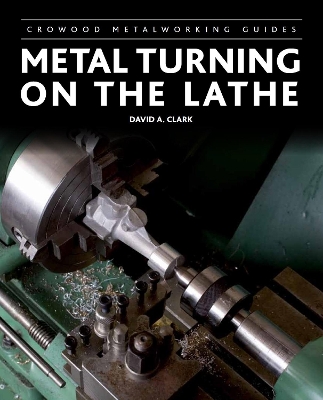

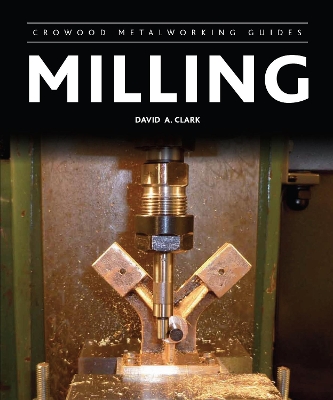

Crowood Metalworking Guides

2 total works

The lathe is an essential tool for all but the most basic of workshops. It enables the engineer to produce turned components to a high degree of accuracy. Often called the 'king of machine tools', it is also very versatile and can be used to make a wide range of engineering components. This new book shows you how to make full use of your lathe safely and effectively in your workshop. Topics covered include: a guide to choosing a lathe looking at different sizes and features available; advice on installing and maintaining a lathe, selecting and sharpening tools, and working with chucks, and finally, instruction is given on a range of techniques ranging from how to hold work in a collet through to cutting a screw thread.

Milling is one of the principal and most versatile machining processes for sizing parts in the workshop. Whether a professional engineer looking for advice, or an amateur looking to install your first milling machine, this book will show you how to make full use of your milling machine safely and effectively, and enhance your milling skills. Focusing on the commonly used vertical mill and vertical turret mill, and with practical advice and diagrams throughout, the book includes: a guide to buying, installing and using a small milling machine and accessories. It also covers basic cutting tool principles and more advanced milling methods, including drilling, tapping and reaming. Instruction is also given on a variety of techniques ranging from work holding in the vice to using a rotary table.